Lom Best Sold High Speed Sugar Packing Machine 5g Vertical Package Machine Sachet Filling Machine for Granule

Overview Product Description High Speed Powder Packing Machine Introduction: This machine is equipped with dual CPU micr

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | LM-PM500 |

| Forming Function | Filling, Seal |

| Driven Type | Electric |

| Material Type | Paste |

| Packaging | Bag |

| Packaging Material | Film |

| Speed | 40 PCS/Min |

| Applicable Packaging Material Range | 1: Liquid, Paste, Sauce: 2: Powder 3: Particles |

| Packing Film Specification | Film Width 50-260mm, Bag Width (25-130mm Seal on T |

| Packaged Bag | 30-180mm |

| Fill Weight | 1-300ml (Depends on The Specification of The Pump) |

| Total Power | Semi -Current 1.5kw Powder 2kw |

| Drive Power Supply | 220V/50Hz |

| Air Pressure/Gas Consumption | 0.4-0.8MPa Gas Consumption 200ml/Minute |

| Usage | Sachet Packing |

| Suitable for | Sachet Pouch Bag |

| Transport Package | Wooden Boxes |

| Specification | 1000*840*1820mm |

| Trademark | Lom |

| Origin | Zhejiang |

| HS Code | 8422301090 |

| Production Capacity | 100/Month |

Product Description

Product Description

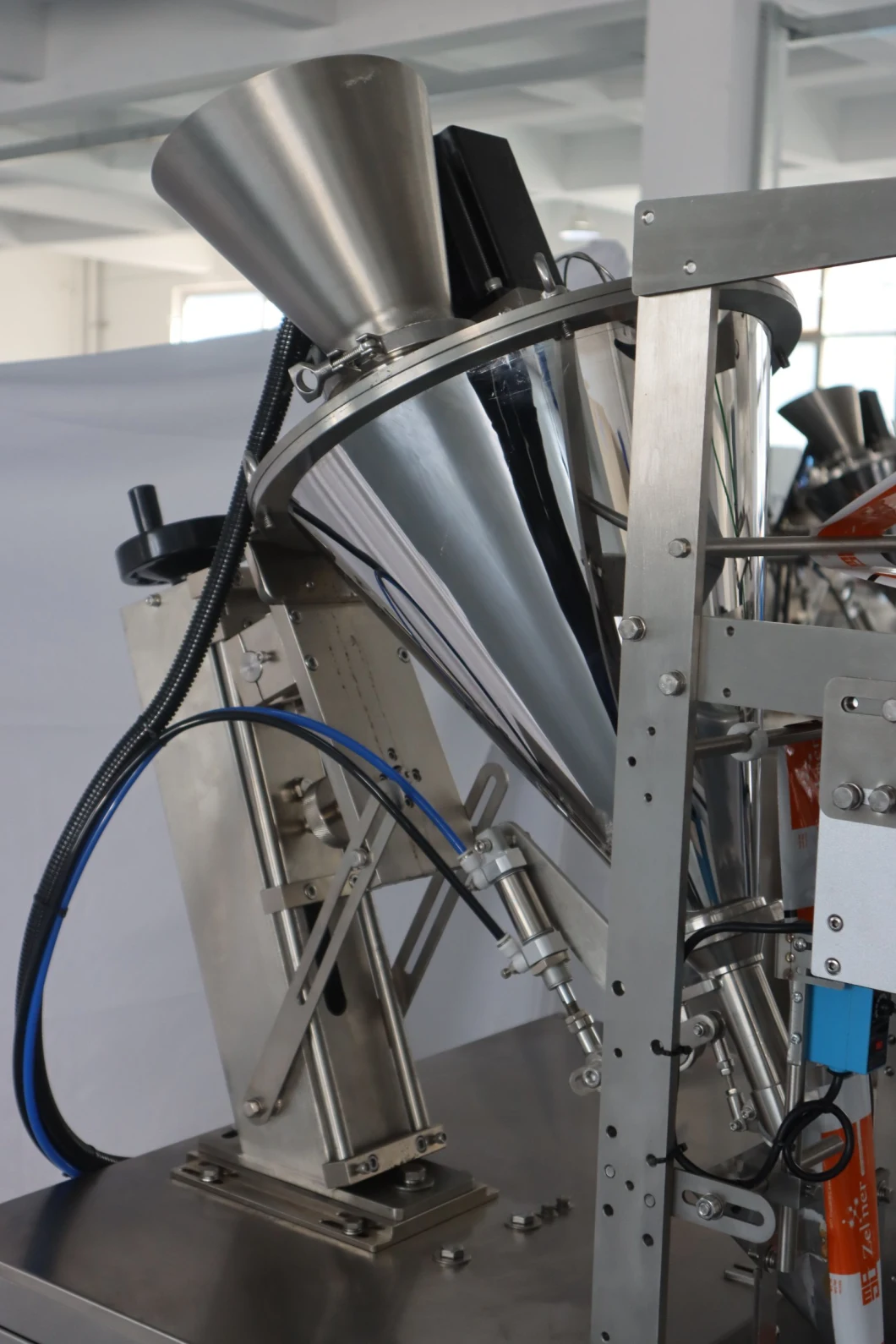

High Speed Powder Packing Machine

Introduction:

This machine is equipped with dual CPU microcomputer control system, 5 inch LCD full Chinese or English display, humanized operation interface, cursor automatic detection tracking, easy to operate.

Equipped with high-precision stepper motor to ensure the accuracy of the cutting position of each packing bag.

Performance:

The use of oblique screw propulsion feeding method, packaging process can directly adjust the weight of packaging, adjustment process without downtime, effectively improve work efficiency. can choose to install the code machine, inflatable, exhaust and vacuum and other devices.

Usage:

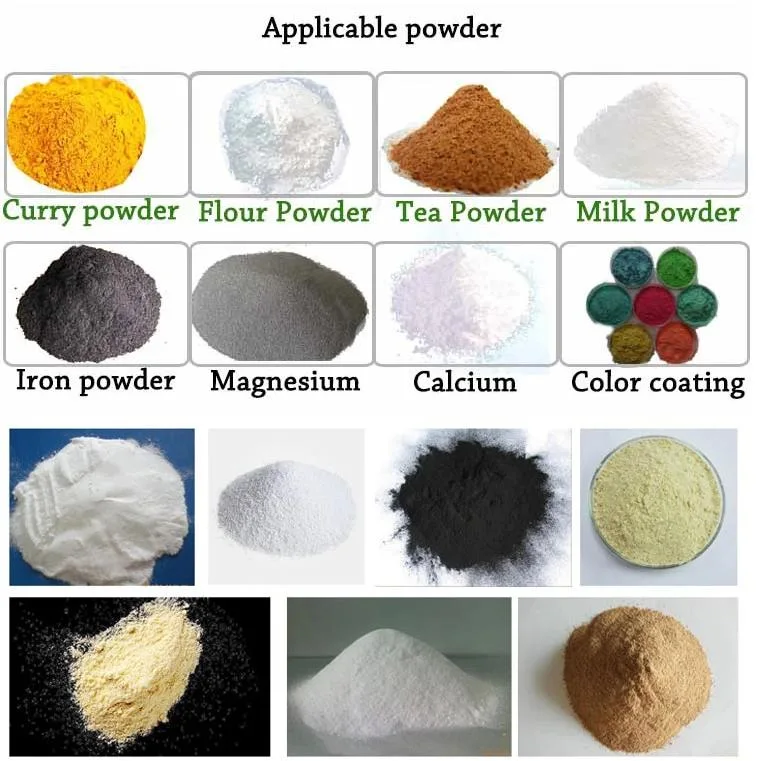

This machine is suitable for milk powder, soy milk powder, sesame paste, lotus root powder, dyeing powder, seasoning powder, powder, etc.

Product feature

♦.50L side opening Hopper ,easy to clean

♦.Packaging powder in 1-100g bag .

♦.Servo motor drive the auger ,got high accuracy .

♦.Have one stir on the hopper ,assure the powder fill in the auger .

♦.Chinese/English or custom your language in the touch screen.

♦.Reasonable mechanical structure, easy to change size parts and clean up.

♦.Through changing accessories, the machine is suitable for various powder products.

♦.We use famous brand electric ,more steady .

♦.Add weighing feedback system ,can assure every bag accuracy.

| Applicable packaging material range | 1: liquid, paste, sauce: 2: powder 3: particles |

| Packing film specification | Film width 50-260mm, bag width (25-130mm seal on three sides; back seal 20-120mm) |

| Packaged bag | 30-180mm |

| Packaging speed | 10-90/bag |

| Fill weight | 1-300ml (depends on the specification of the pump) |

| Total power | Semi -current 1.5kW powder 2kw |

| Drive power supply | 220V/50Hz |

| Air pressure/gas consumption | 0.4-0.8MPa gas consumption 200ml/minute |

We have service outlets in almost every country and will provide customers with thoughtful door-to-door service. Even if the machine fails, there is no need to worry at all. Our after-sales service will make you very assured! We look forward to long-term cooperation with customers and grow together with customers.

- One-to-one teaching by professional engineers

- 24 hours online service

- Engineers come to repair, give any help

- Complete video teaching to ensure one step in place

About Lom

We produce our own machines, give customers the best prices and solutions, and have a very good freight forwarding company, which makes our transactions more smoothly. Almost all customers are satisfied with our services, and we have tens of thousands of Counting customers to repurchase, I hope to have confidence in us.

Q1:What material does the machine use?

A:The machine uses 304 Stainless steel.Completely consistent with food inspectionQ2:Could your machine meet custome made?

A:We will supply you proposal as to your specific requirement,and each machine is customized to satisfy customer's need well.

Q3:How long is the delivery time?

A:Usually 15 days after receiving deposit.Q4:What's speed?

A:more than 40 pcs/min.

Q5:Are there any other accessories?

A:The machine is equipped with a mixing function, which can add the date coding machine and the promotioner .

Q6:What hazard warnings does the machine have?

A:Do not touch the machine's operation part at running, it is very safe outside the machineQ7:.Can you provide good after-sales service?

A:LOM pay attention to the after-sale service, we build a aftermarket team to help the customers deal with the installation, replacement of accessories, operation the device when the machine in using. We promise to provide superb quality and after-sale service, and is very pleased with customized orders.

Q8:Why chose us ?

A:LOM focus on improving the quality of the production and after-sale service. Our competition:Professional sales team and technicians

- Andvanced equipments and technology

- Responsibility for our mistake

- Efficient solution

- Strict QC regulate

Related Products

-

![China Manufacturer Velour Terry Cloth Fabric Disposable Slippers Hotel]()

China Manufacturer Velour Terry Cloth Fabric Disposable Slippers Hotel

-

![100% Polyester Customized Microfiber Beach Sports Gym Travel Towel Bath Towel Microfiber Towel]()

100% Polyester Customized Microfiber Beach Sports Gym Travel Towel Bath Towel Microfiber Towel

-

![OEM Closed Toe Disposable Hotel Slipper]()

OEM Closed Toe Disposable Hotel Slipper

-

![Wholesale Natural Handmade Organic Black Bamboo Charcoal Soap Cleaning Whitening Face and Body Bath Bar Hotel and Home EVA Flower Thailand Soap Beauty Skin]()

Wholesale Natural Handmade Organic Black Bamboo Charcoal Soap Cleaning Whitening Face and Body Bath Bar Hotel and Home EVA Flower Thailand Soap Beauty Skin